CNC Machine

Has your equipment broken down? Is your CNC machine tool faulty?

ASERTI Electronic (Société CNC Services) offers a maintenance service to make industrial clients’ stock of numerically controlled machine tools go the distance.

In industry, and more particularly in the metallurgy and metalworking processes, we provide our clients with a fast, reliable, cost-effective maintenance service for numerically controlled machine tools. To diagnose your problem and provide you with a solution as quickly as possible, the ASERTI Electronic teams working with CNC machine tools are ready to support you.

Comprehensive expertise

Our technicians hold expertise across many areas from electronics, electrics and mechanics to hydraulics and pneumatics, guaranteeing you a better service, with a return-to-operation rate greater than 90% from the first visit, whatever the brand, type or generation of your numerically controlled machine tool.

A mastery of mechanics

Our teams have the skills to diagnose and repair all the mechanical components in numerically controlled machine tools:

- Ball screws

- Axis motors

- Spindle motors

- Pins

- Electrospindles

- Slides and more.

Ball screw expertise

After disassembly by you or us, ASERTI Electronic carries out our ball screw expertise on our premises.

Depending on the condition and wear of the screw, the following operations will be carried out:

- Changing balls, brushes and gaskets

- Preload adjustment

- Lapping the screw thread,

- Repairing or manufacturing new nuts

- Chrome plating and grinding end bearings

Once repaired, the geometry is checked.

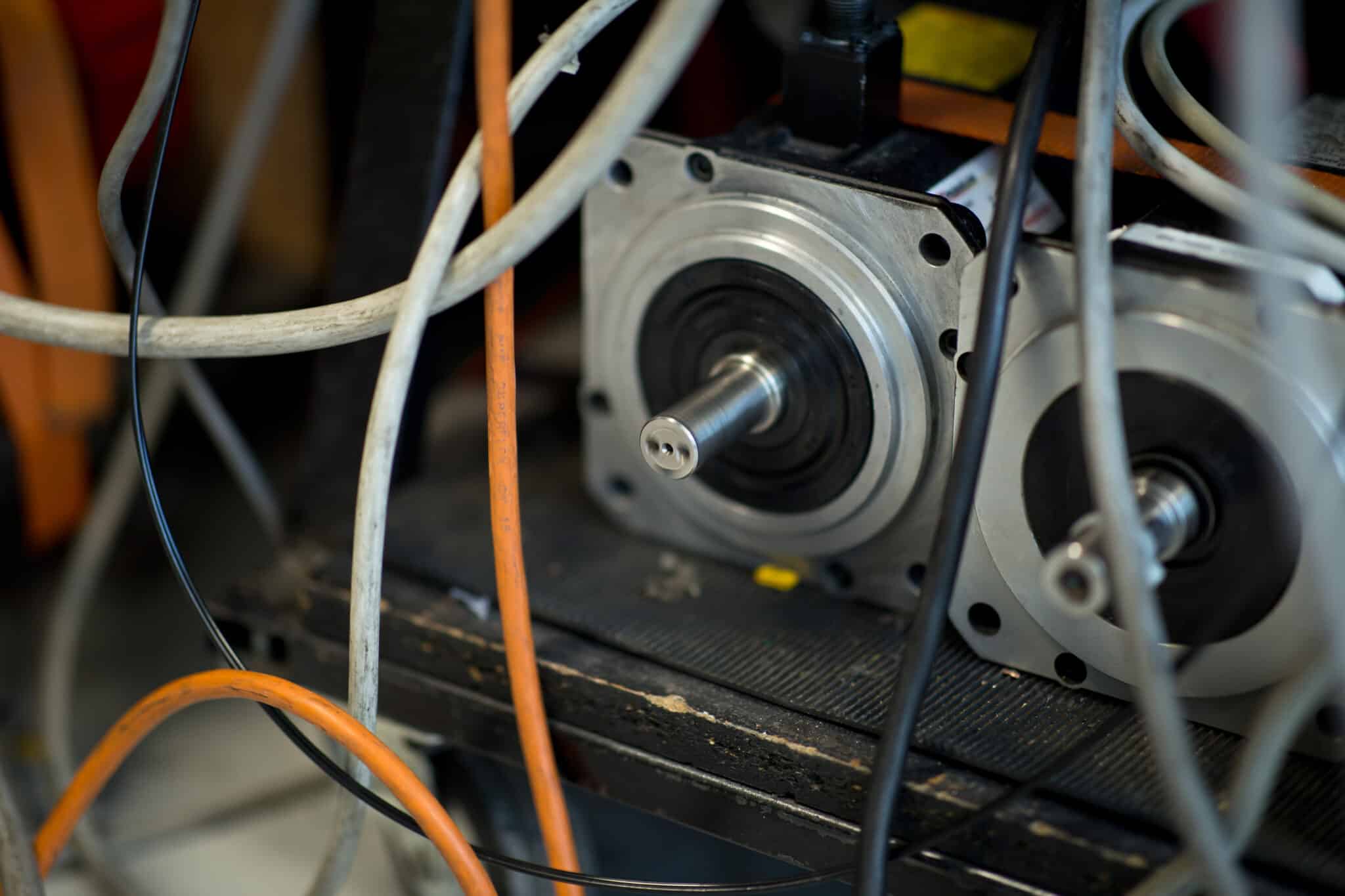

Servomotor expertise

Whatever the brand, be it Fanuc, Siemens or Yaskawa…

Whatever the technology, whether brushless, direct current or spindle motor…

Our teams have the skills to repair and prevent damage to servomotors.

With a workshop dedicated to this expertise where skills and resources are brought together, ASERTI Electronic ensures the overhaul and repair of your servomotors, taking into account your time constraints.

Numeric control expertise:

The numeric control is the control cabinet that receives machining instructions in the form of a punch tape, magnetic tape, or information from a PC. Sometimes, these machines are named after the system with which they are equipped. So, we are referring to a numerically controlled lathe, or a numerically controlled milling machine, as opposed to a conventional lathe or ordinary milling machine, where the movements are controlled by hand or by an automated system in a set manner.

We have provided specialist maintenance and development on the majority of FANUC CNC Controls since 1985:

- Changing PLC (I/O automation and NC signals part).

- Modifying/Adding servomotors, variators and configurating the latter.

- Full configuration.

- Inserting additional axes.

- Interfacing with different devices.

- Interfacing with a loading or palletising robot

- Retrofit centres for 3 axes, 4 axes and 5 axes simultaneously (CNC can manage 32 axes).

- Custom machine design

- HMI development to design dedicated operator interfaces

Free quote

Ask for a quote