Electronic equipment maintenance

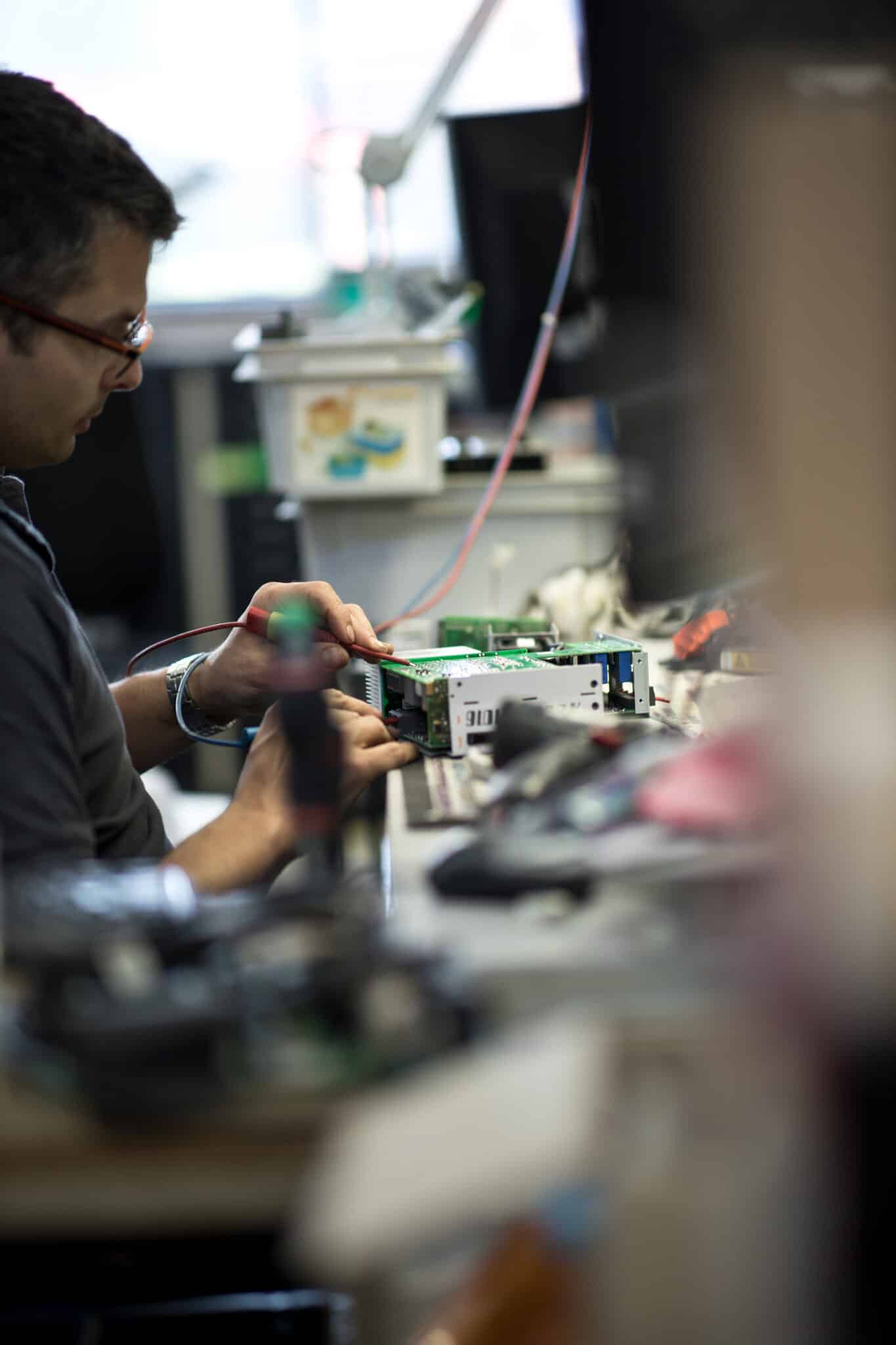

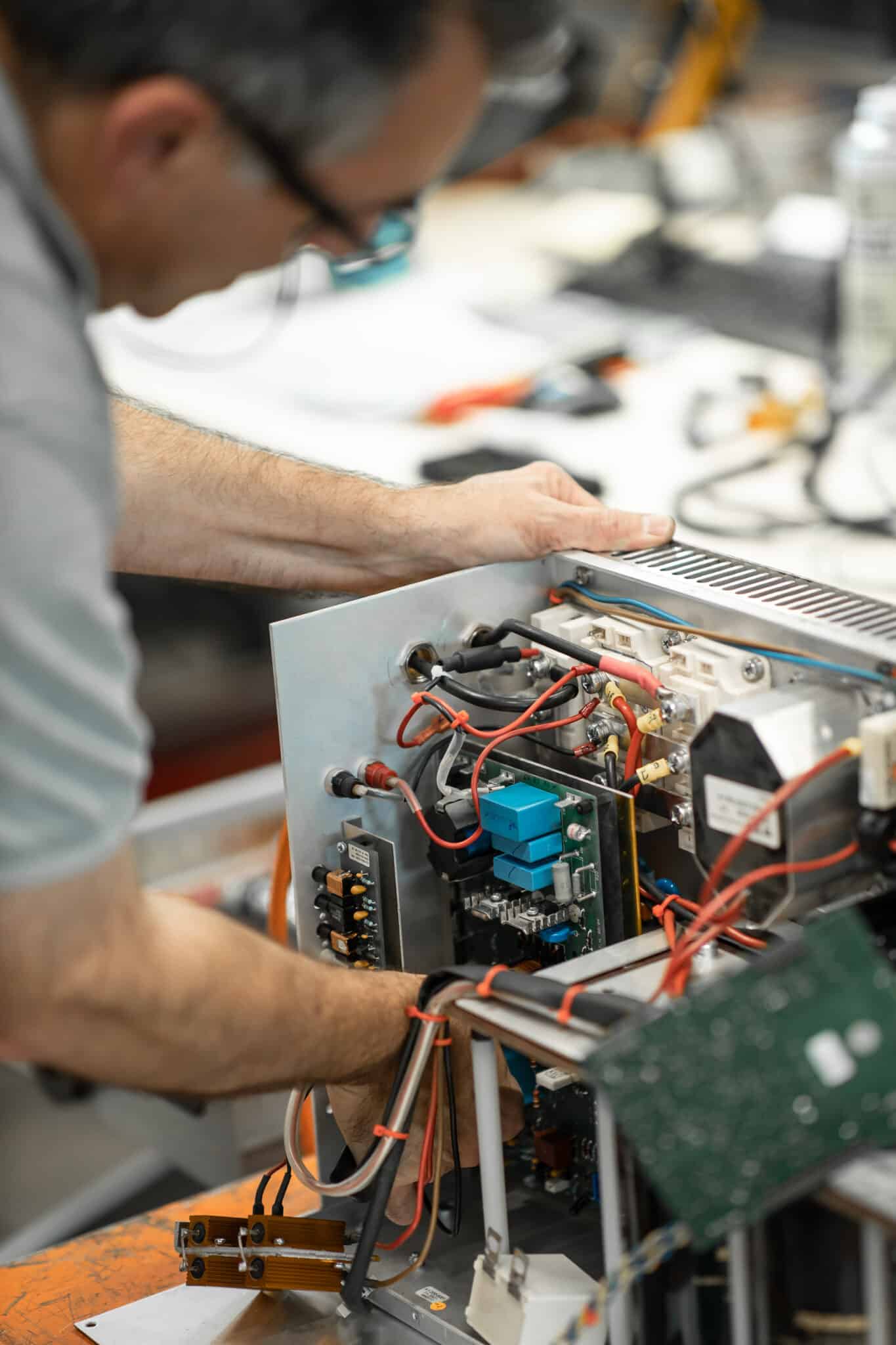

ASERTI Electronic assesses, repairs and makes electronic equipment for your systems more durable,

whatever the type and brand of equipment.

Our repair process

Our business management tool allows us to ensure perfect traceability in every sector, and to constantly measure the quality of our service.

A business number is assigned to each piece of equipment, and we can keep you informed of the progress of our work at any time.

The main stages of the electronic equipment repair process are:

- Expert assessment of hardware (static signature test)

- Repairing equipment

- Preventive action by replacing components with a limited lifespan (capacitors, optocouplers, relays, etc.)

- Refurbishing equipment (cleaning, mechanical repairs, etc.)

- Repairing welds and connections

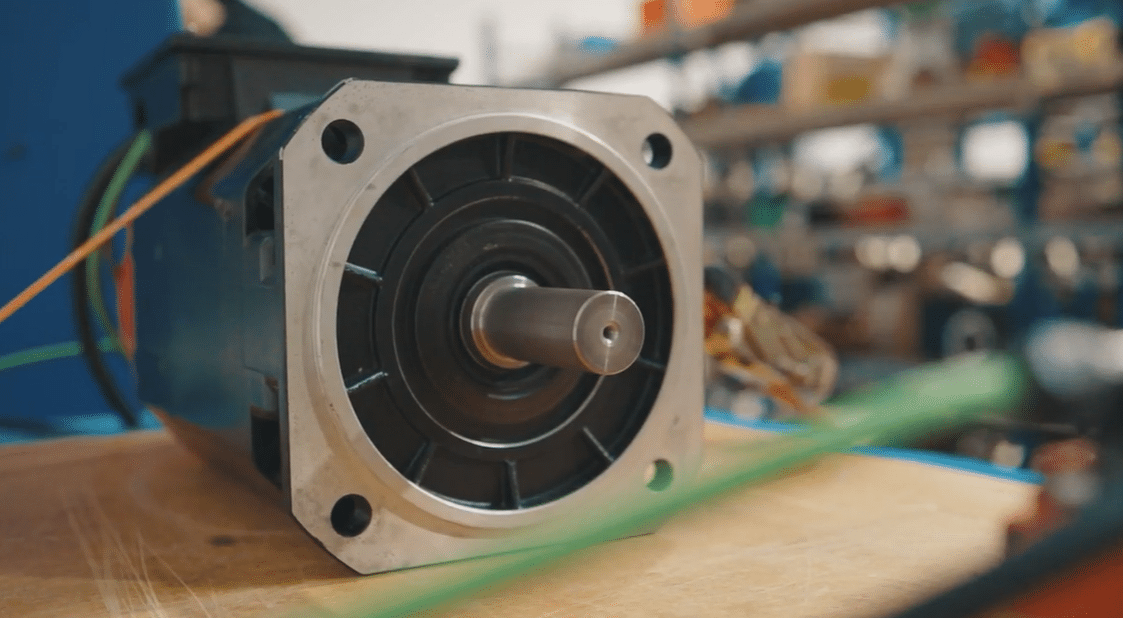

- Testing equipment, either on a dedicated bench (dynamic), for a specific component, or on-site

- Providing a service call report at your request

Our skills network

Our technicians have a minimum HND-level initial training in Electronics, with the majority also having solid experience in industry. To support their regular external training, we have set up an ASERTI Academy, capitalising on the experience of our oldest employees to preserve and pass on our expertise to newcomers.

At the same time, we have a skills capitalisation and exchange tool which brings together everyone’s best practices and allows you to benefit from the strength of our Group (feedback, shared documentation, supply source for components, etc.).

Combined with all our tools, this way of organising means that we can guarantee you the same quality of service in all the areas where we operate, while staying in immediate proximity.

Our resources

Each of our technicians has powerful tools:

- Individual soldering/desoldering station

- Repair Station for Surface Mount Components (SMT)

- Binocular magnifier for inspecting welds

- In Situ Tester, U/I Signature Analyser, Component Programmer

- Portable workshop oscilloscope, insulation monitoring device, process calibrator…

We also have nearly 400 test benches shared throughout the network, to check equipment function after repair:

- SIEMENS S5, S7 programmable logic controllers; TELEMECANIQUE Series 7, Micro, Premium, Twido; ALLEN BRADLEY; APRIL 2000/5000, SMC, and more.

- SINUMERIK 810/820/850, 840C, 810D, 840D numeric controls; NUM 760/1060

- Axis and positioning controls: SIEMENS SIMODRIVE; SCHNEIDER LEXIUM; ELAU MC4 and PMC-2; INDRAMAT DKC, HDS/HVR, DDS, DIAX03/04; NUM MDLA/MDLS/MDLD, etc.

- Load banks for frequency converter

The effectiveness of our means for testing and associated procedures are constantly monitored to improve their performance.