Drive system maintenance

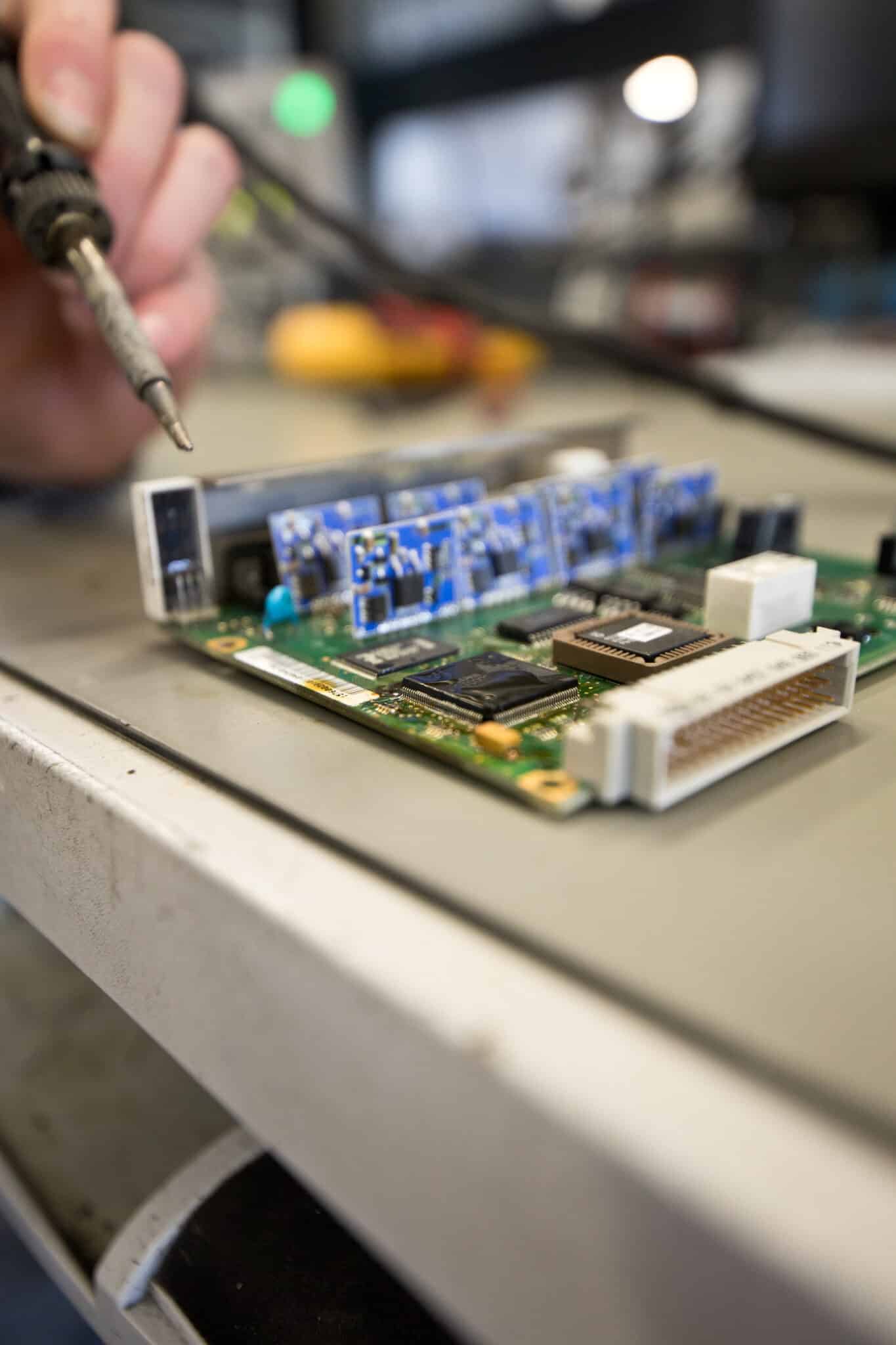

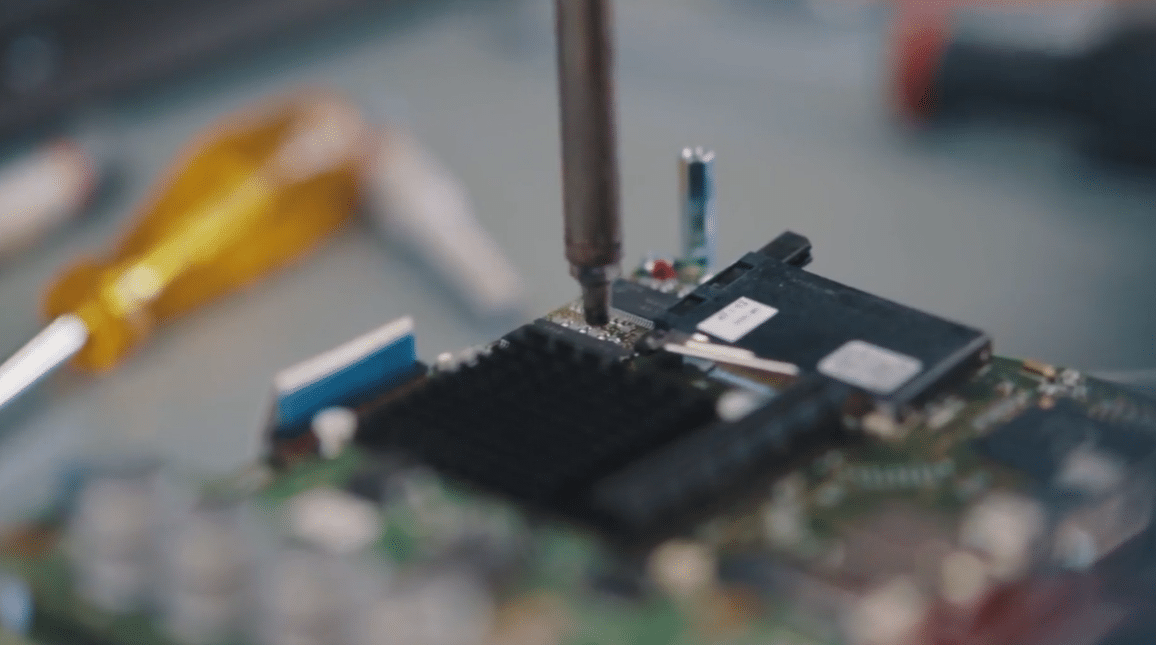

ASERTI Electronic assesses, repairs and makes all the elements of a drive system more durable, whatever the technology and brand of equipment.

Our strengths

- Expertise across the complete drive system

- Access to original parts

- Providing technical summaries

- Responsiveness

- Global stock management

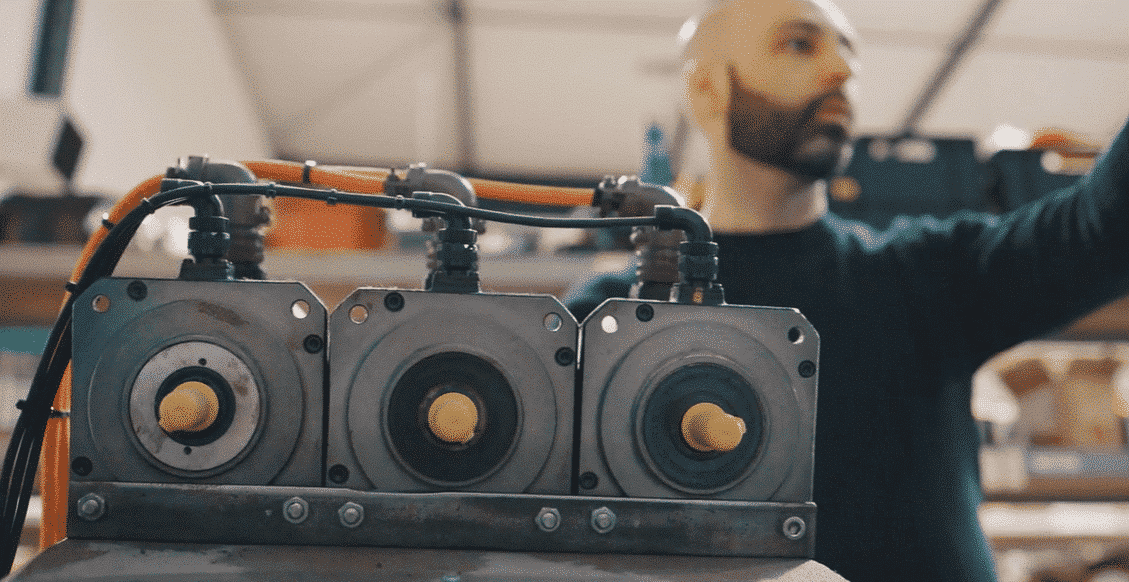

Variators

Technology:

– Frequency

– Direct current

– Brushless

Means for testing and dynamic testing on benches:

Axis and positioning controls: SIEMENS SIMODRIVE; SCHNEIDER LEXIUM; ELAU MC4 and PMC-2; INDRAMAT DKC, HDS/HVR, DDS, DIAX03/04, NUM MDLA/MDLS/MDLD, etc.Axis and positioning controls: SIEMENS SIMODRIVE; SCHNEIDER LEXIUM; ELAU MC4 and PMC-2; INDRAMAT DKC, HDS/HVR, DDS, DIAX03/04, NUM MDLA/MDLS/MDLD, etc.

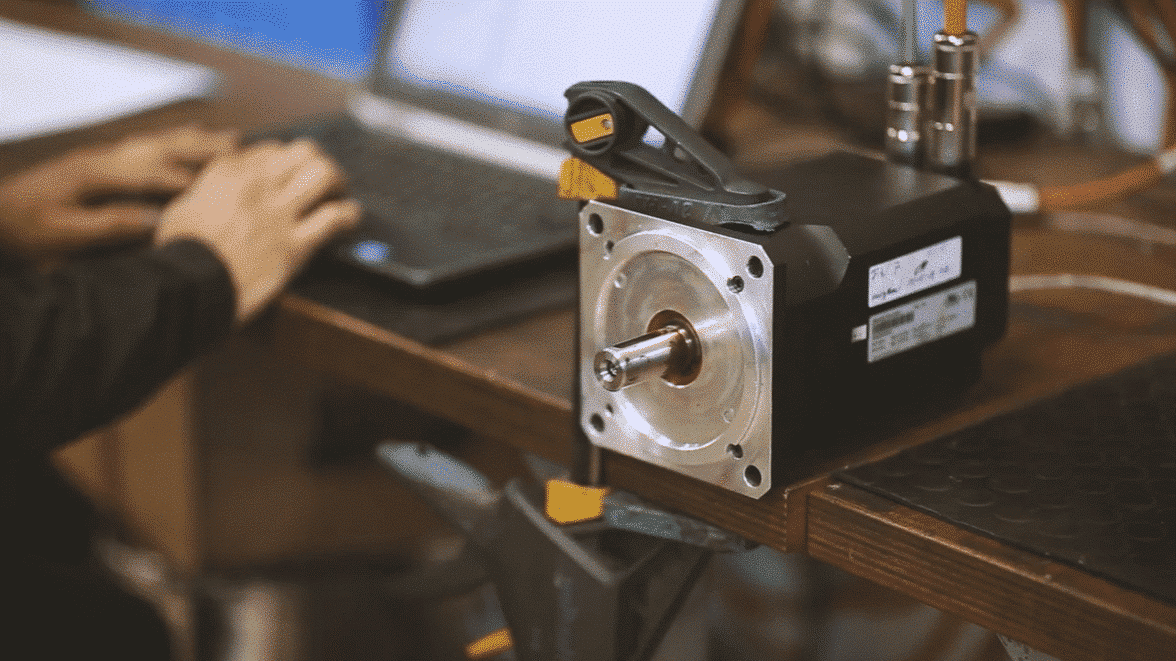

Servomotors

The main stages of the servomotor repair process are:

- Disassembly and expert assessment of equipment

- Testing different subassemblies (Stator, Rotor, Position sensor etc.)

- Equipment repair and damage prevention (bearing, seal, etc.)

- Cleaning / Painting

- Vibration test

- Tests on specific test benches

Means for testing and dynamic testing on benches:

- Winding

- Balancing

- Vibration check

- Braking torque

- Demagnetising/Magnetising